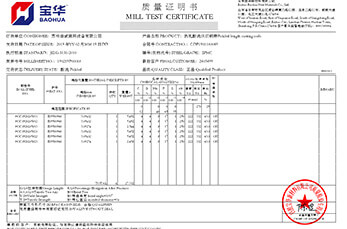

We always purchase steel from certified steel mills or distributors who provide official steel mill certification for each shipment.

- Tell: +86 512 52438861

- Email: james@jcjh.com

During the past decade, our factory has successfully adapted two distinct production methods for standard and custom products in order to better serve our customers’ needs. We have achieved full automation for standardized products and high efficiency for customized products. Here you will find information on how we work together with you step by step from the quotation and design process to delivery.

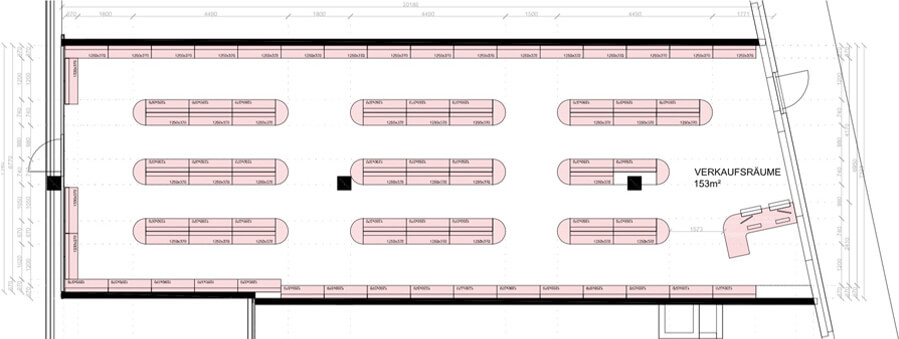

Floor plan estimation: generate the list of product component, specification, and quantity from the floor plan layout

Make quotation based on the product list

Confirm details on the standard products: color, branded logo, packaging specification, and etc.

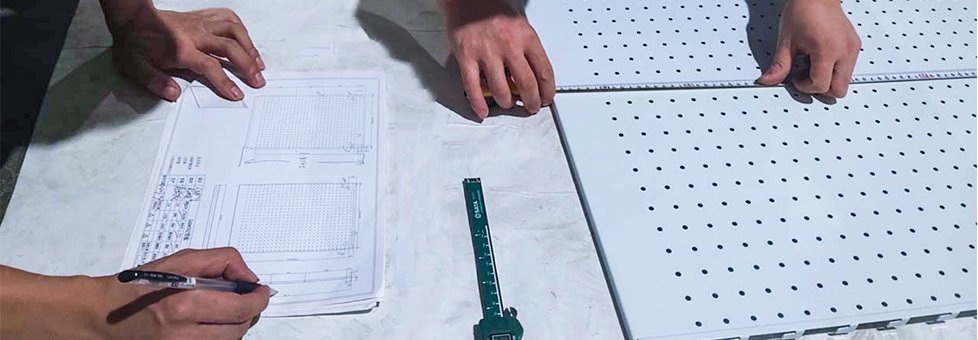

Make quotation based on customer’s existing drawing or make our own design and drawing based on customer’s requirement

Design drawing modification and confirmation

Confirm quotation, tooling cost, and packaging specification

Prototyping and sample confirmation

Our guarantee of good product quality starts from certified and environmentally friendly raw materials.

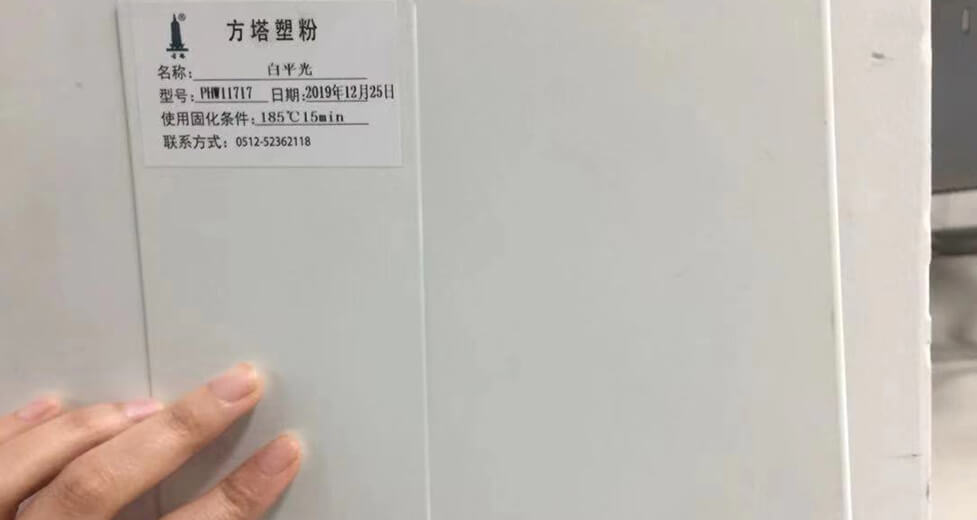

Steel and coating powder are the two main raw materials for our products.

We always purchase steel from certified steel mills or distributors who provide official steel mill certification for each shipment.

Some of our clients would require additional 3rd party inspection such as SGS on the raw material used for each shipment and we have passed all the inspections during the past 8 years with an approval rate of 100%.

Unlike other suppliers, we know very well about the unique properties of each type of steel, and we match the most suitable type of steel with our products.

We also purchase the coating powder from professional manufacturers that use high quality and environmental-friendly material only. We require our coating powder supplier to submit the lab testing reports on their raw material and finished products every quarter to ensure the coating powder we receive is durable, long-lasting, and greener.

We use fully automated production lines for our standard shelving and racking that produce directly from the steel coil to the finished raw products with the help of robotic arms and conveyor belts.

Automatic Shelf Production Line

Automatic Base Leg Production Line

Upright Roll-forming Line

Semi-automatic Wire Production

Automatic Bending Center

Robotic Welding

Our skillful workers are able to make any kinds of custom metal products with help of advanced production equipment.

In-house Tooling Production

CNC Cutting

Laser Cutting

CNC Bending

Manual Welding

Punching and Pressing

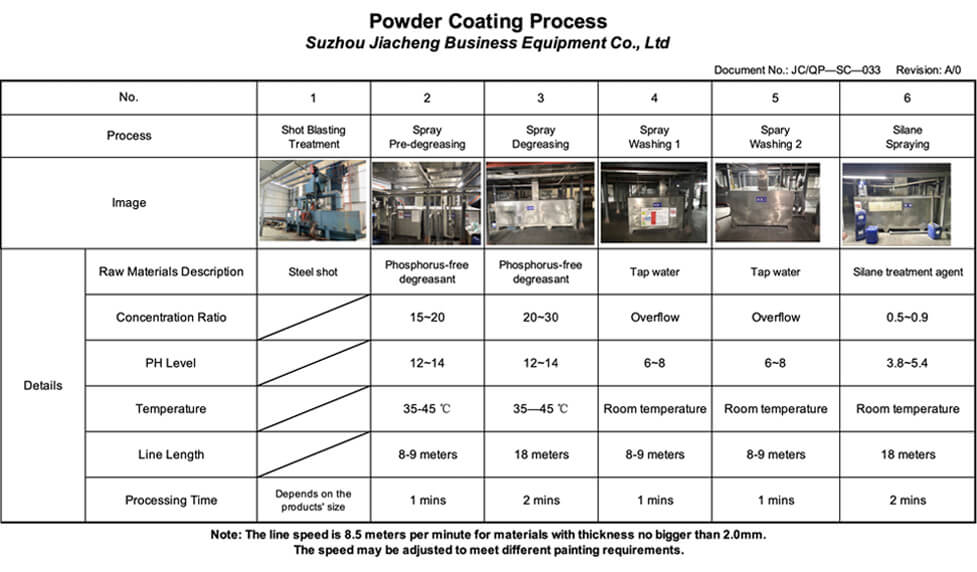

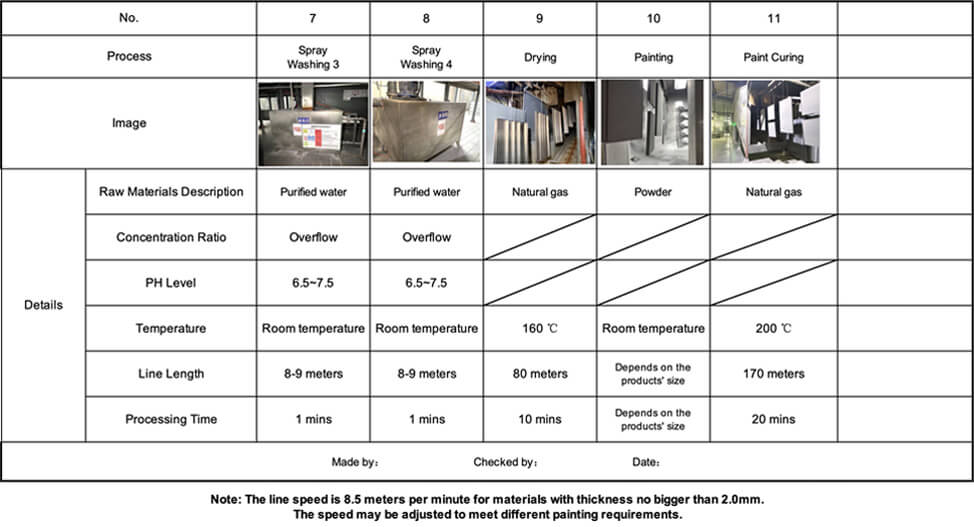

Powder Coating is the last and one of the most important procedures in the production process. We are very proud of our highly advanced automatic powder coating lines that provide durable, consistent, and colorful surface for our products.

We use more expensive phosphorus-free degreasant and silane treatment agent in our pretreatment because we care about our environment. All the used chemical products will be collected and processed in our in-house waste recycling station before sending to state-owned waste recycling station for further processing.

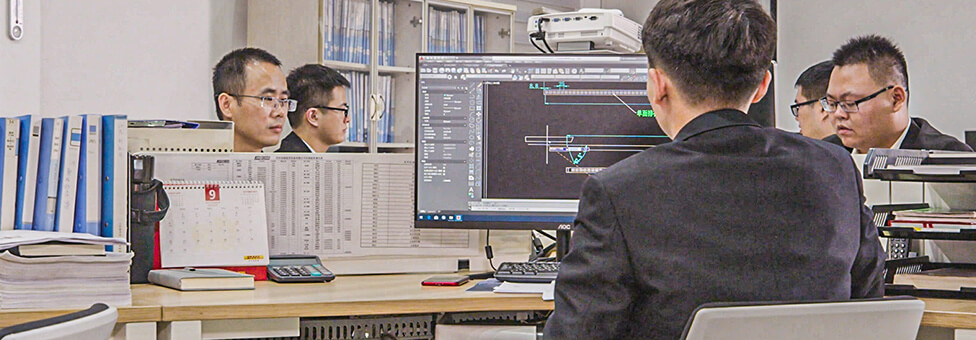

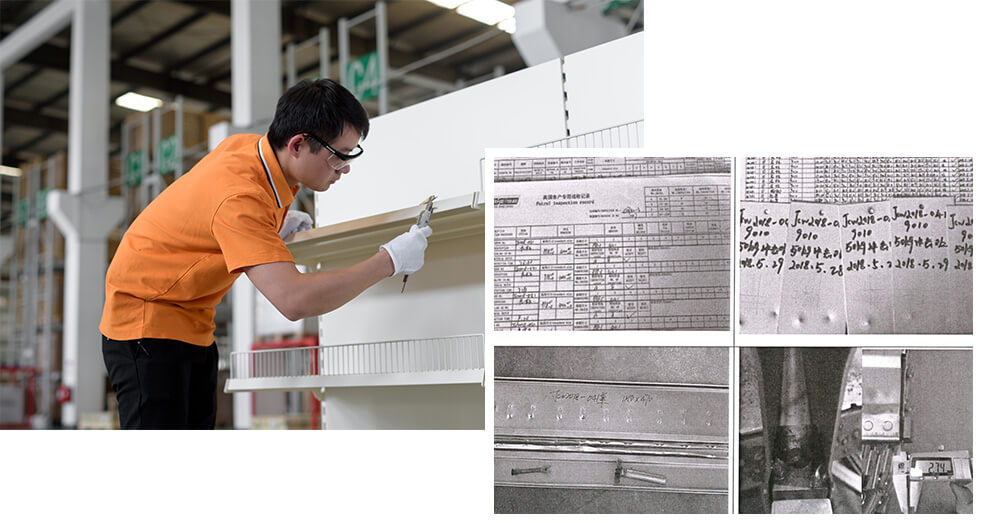

The precision starts with the high requirement of the drawings from our technical department. The production strictly follows the instructions from the drawings. Our QC team will do the random inspection during the manufacturing process. After production, we assemble the product before and after powder coating to check the sizes. We generate a detailed QC report before sending out the products.

Our expertise in warehousing and logistics ensures the safe delivery of various kinds of products.

From decades of shipping experience, we learned the safest but space-saving packaging method for each different component.

We also assist customers in designing a flat packaging method so the products can be ready-to-sell when leaving our factory.